ENHANCED EFFICIENCY AS A RESULT OF HARDWARE CUSTOMIZATIONS

Your Industry Challenge, Our Solution

WHERE TRUST MEETS TECH:

GETAC’S REAL-WORLD SOLUTIONS SPAN MULTIPLE INDUSTRIES

Every company has its unique challenges. Getac is known to provide industry-tailored, rugged computing solutions that cater to your specific operational needs. Whether boosting efficiency, prioritizing safety, or lowering total cost, we make it our mission to develop a core understanding of your business goals. We consider your pain points, the context of your day-to-day work, and your desired outcome, which all lead to our perfect-fit solution— one with only the capabilities you need and want. We’ve collaborated with businesses in various fields and have generated hard results for each and every one of them. Let us do the same for you.

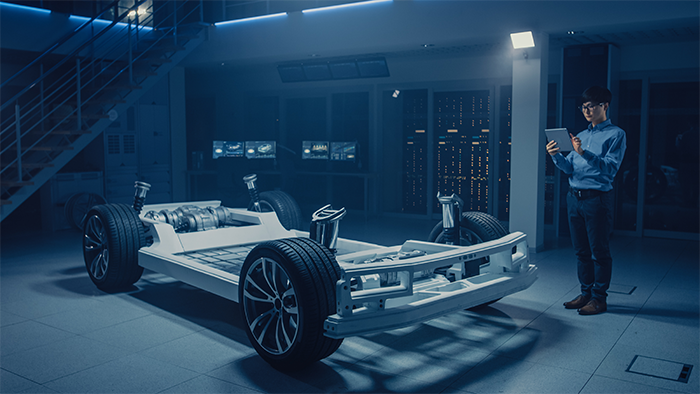

CREATING A RELIABLE WORKFLOW IN AN AUTOMOTIVE WORKSHOP

Avoiding Disconnection with A Custom USB Type-C Cable and Port Locker

Recommended for:

AUTOMOTIVE

MANUFACTURING

THE INDUSTRY & COMPANY

Custom tablets for day-to-day operations in automotive workshops

When doing vehicle diagnostics, automotive engineers need computing power and ruggedness. When it comes to custom tablets, they seek durable devices with less RMA (Return Material Authorization), good after-sales support, and further technical consultation. It is also key that the devices used in these workspaces are human-centered, considering the users' mobility, workflows, and needs.

THE CHALLENGE & PAIN POINTS

Workflow interruptions caused by loose cables

Because engineers are constantly moving around in the automotive workshop— to access different parts of the vehicle or to move between stations or service bays, they must be able to have full mobility with the tablet while maintaining connection. Cables have a tendency to fall out or be pulled out in motion, interrupting their workflow. Having the I/O port locked would help them maintain this connection to the system, significantly reducing friction, time, and frustration. Many engineers even rely on specialized diagnostic tools and equipment that may use unique or legacy I/O connections, so locking these ports can help ensure better compatibility and prevent accidental disconnection and data loss.

THE TAILORED SOLUTION

Locking I/O ports and custom USB type-C cable to enhance reliability

Getac’s F110, a rugged tablet that can operate with exposure to a workshop's dust, grit, and grease, was a clear choice. This device allowed their VCI (Vehicle Communication Interface) to communicate with their automotive service dealer network. Getac was able to customize an extension cable from a USB Type-C to a female USB Type-A connector. When plugged, the USB Type-C plug end had two thumb screws on either side to lock the cable onto the F110. Having this cable fixed enhanced the reliability and durability of the workshop by preventing disconnection and allowing them to move freely through the shop.

Apart from the main customization, the F110’s new design also offers a high-capacity battery as an optional upgrade, a vehicle power adapter to extend battery life even further, and a detachable keyboard to allow adjusting the display at a wider view angle, all logistical details that make the device a better fit for the industry and the workers who use them daily.

THE RESULTS & BENEFITS

Simple device customizations lead to a great impact on the company

This automotive company has been a long-time user of Getac’s products due to the rugged build of the devices and excellent after-sales support. However, the flexibility in terms of technical customization requirements sets this solution apart. In this case, a seemingly simple customization to the tablet connector solved a specific issue in this space and increased the efficiency of operations in the workshop. The flexibility, reliability, and distribution efficiency Getac had to enhance further the device made all the difference for the company.